Edible Oil Filling Machine and Equipment Manufacturer & Supplier in India

Welcome To Our Site

Shree Bhagwati Machtech India Pvt. Ltd., one of the leading manufacturer and exporter of Filling Machines for filling Edible Oil, Juice, Olive Oil, Cooking Oil, Edible Oil Packing Machine , Lubricant Oil Filling Machine , Edible Oil Filling Machine , Liquid Filling Machines , Oil Filling Machine , Capping Machines , Bottle Filling Machine, Oil Packaging Machine, cooking oil filling machine, oil filling machine, mustard oil filling machines and automatic engine oil filling machine, Honey filler, Beverage, Ice Cream, Peanut Butter, Petroleum, Jelly, Jam, Syrup, Milk, Soymilk, yogurt, Pure Water, Beer, Eye Drop, Engine Oil, Liquid, Motor Oil, Lubricating, Shampoo Etc.

Many companies wax eloquent about quality but few make the commitment to deliver it. Thousands of machineries manufactured by us are running flawlessly today, and most of the pharma industries confirms the fact that we are really earnest when we assure you that the products we manufacture and services we provide are of the highest quality.

We welcome any question or

requirment you may have for our products...!

Years Experience

Worldwide Installations

Offices Worldwide

Hardworking People

Our All Products

- Application: This type of piston filler is best suited for viscous products that are paste, semi paste, or chunky with large particulates for Heavy sauces, salsas, […]

- Automatic Piston Servo Paste Liquid Filling Machine Application: Automatic Piston Servo Paste Liquid Filling Machine is suitable for the automatic filling of various bottle types in […]

- Automatic Bottle Filling Capping And Labeling lines Application: Suitable for automatic filling, capping, and labeling of various liquid products. Round, flat, square, and other shaped […]

- Liquid Bottle Gravity Filling Machine Application of inline gravity filler: It is an economical filling machine that is best suited for liquids with very thin viscosities […]

- Automatic Bottle Ketchup Filling Line Application of bottling machine for ketchup, hot sauces, fruit jam: It is suitable for the quantitative filling of various oils such as […]

- Sauce/ Ketchup/ Paste Bottle Filling Capping and Labeling Machine Application: This production line is suitable for the filling of some large particle sauce products, such as: […]

- Perfume Filling Machine Manufacturer, Perfume filler & Filling line Our product range includes a wide range deliver the perfume crimping machine, bottle crimping machine, filter press, […]

- We are Linear Inline Tomato paste Filling machine, sauce filling machine, butter filling machine, oil filler, Mayonnaise filling machine filling machine for bottle and Jar , […]

- We have wide range models of edible oil bottle filling machine, fully automatic oil filling machine, vegetable oil filling machine, mustard oil filling machine, edible oil […]

- manufactures a variety of liquid filling machines such as inline filling systems. Such systems are capable of filling almost any product into an assortment of bottle […]

- Motor oils, engine oil, lubricants is any of various oil compression base oils with various additive, particularly anti-wear additive in additions to detergent, dispersant and for […]

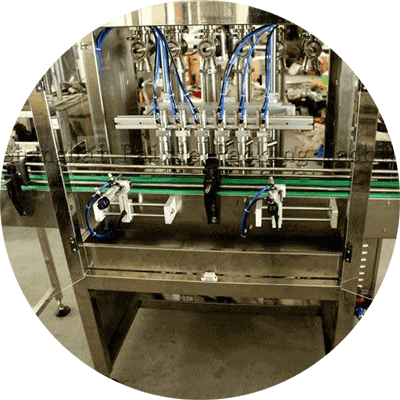

Oil Packaging Line Consists of Linear Filling Machine, Capping Machine, Induction Sealer, Labelling Machine, Box packing Etc.

- 5 Liter Oil Packing Line

- 200 ml to 1 Liter Oil Packing Line

- 15 kg Oil Tin Filling Line

- Edible Oil Packing Line

- Vegetable Oil Packing Machine

- Mustard Oil Packing Line

- 25 Liter Jerry Can Filling Line

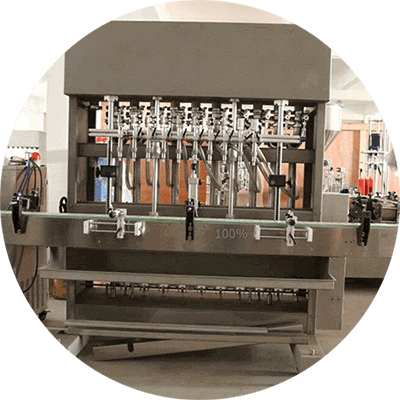

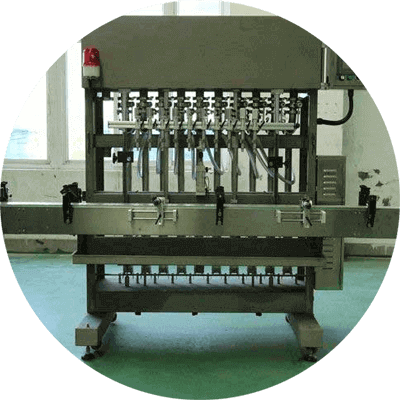

- 6 & 8 head Oil Packing Line

- 3 Liter Jar Oil Packing Machine

- Oil Filling and Capping Machine

- 200 ml oil Filling and capping machine

- 2 Liter and 5 Liter Jerry can Oil Filling Machine

- High-speed oil packing Machine

- high Speed Oil pet bottle Packing Line

- 15kg/15 Liter Oil Tin Packing machine

- Automatic Tin Packing Machine

- 500ml to 5 Liter Oil Packing Machine

- 5 Liter,20 Liter Bucket Filling Machine

- Semi-Automatic Load-cell base oil filling machine

- Automatic Edible Oil Sunflower Pouch Packing Machine

- Automatic Oil Packing Line Groundnut oil, Edible Oil Pet bottle.

- Automatic Edible Oil Tin Filling Machine

- Automatic Edible Oil Sunflower Oil Filling Machine up to 5 Liter

- Automatic Oil Packing Machine 500ml to 5 liters

- 15 Liter Weighmetric Oil Tin Filling

- Sunflower Oil Jar Filling Machine

- Automatic 15kg Edible Oil Filling Machine

- Automatic Jerry Can Oil Filling and Capping Machine

- Automatic 15 Kg Oil Tin Weight Base Filling Machine

- Automatic Pail/Jerry Can Packing Line, Oil Packaging machine

- Automatic Tin Filling Machine 15liter/15KG, weigh metric filler, Edible Oil Packing Machine

- Weight base 15KG/15Liter Edible Oil, Groundnut Oil Tin Filling and Sealing Machine

- Automatic Weight base Oil Filling Machine for 15Liter/15KG Tin

- Mustard Oil Bottle Packing Machine 500ml to 5 Liter

- Automatic Weight base Jerry Can Filling Machine, edible oil Packing machine

- Edible Oil Filling Machine

Lubricant Oil Filling Machine

Our range of products include automatic lubricating oil filling machine, lubricant filling machine, lubricant oil filling line., automatic engine oil filling machine., automatic engine oil filling line. and engine oil filling machine..

Edible Oil Packing Machine

Oil Filling Machine

Leading Manufacturer of soybean oil packing machine., 5 liter oil filling machine, 1l 2l 5l oil filling machines, engine oil packing machinery, mustard oil 15 kg tin packing machine and automatic edible oil packing machine

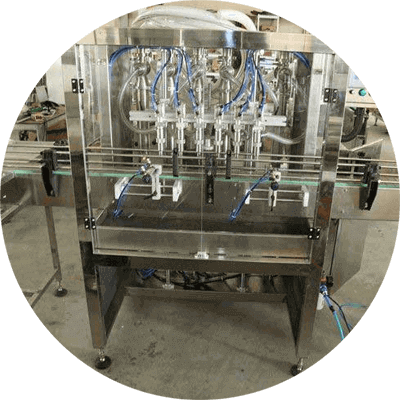

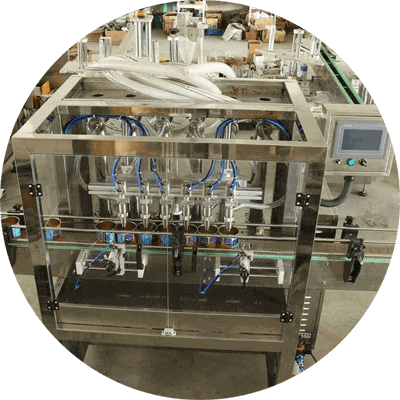

Our range of products include oil filling and packing machine, sunflower oil filling machine, mustard oil filling machine 500m and 1 litre, semi automatic mustard oil packing machine, automatic oil jar filling machine and automatic oil packing machine.

Liquid Filling Machines

Our range of products include load cell base filling machine, vegetable oil filling machine, automatic volumetric liquid filling machine, oil filling machine, oil packaging machine and liquid filling machine.

Manufacturing Unit

Oil Filling Machine and Equipment Manufacturer & Supplier

Shree Bhagwati Group is Leading manufacturer, supplier, trader and exporter of Packaging Machines offers Filling lines for the Food, beverage industry and FMCG producers: process technology, filling technology, packaging machines.

FILLING MACHINES MANUFACTURER

Variety of Filling Machines

There are many varieties of filling machines accustomed to package the range of products in today’s marketplace as well as liquids, pastes, chunky merchandise, powders, granules, tablets, capsules, etc. Most filling machines are obtainable from semi-automatic work surface versions of all the high-to-high speed line machines, as well as rotary fillers.

There are sometimes totally different filling varieties in step with different filling standards.

According to the degree of automation, the categories of filling machines are manual filling machines, semi-automatic filling machines, and fully automatic filling machines.

Manual Filling Machines

These are manually operated and can need no power or electrical supply. they’re typically used for packing extremely viscous liquids like creams, gels, and shampoos however will do for medium-consistency liquids. Manual filling machines are ideal for little-scale productions or laboratories wherever they’re going to give a better output speed and enhanced accuracy than once the liquids are poured by hand. they’re ideally used for filling bottles with regarding 600ml capacities and have a production speed of 15-900 bottles/hour.

Semi-Automatic Filling Machines

These are quicker compared to manual machines and can suit medium and tiny-scale production processes throughout a high-volume season. Semi-automatic machines are designed with nozzle, syringe, and piston elements that guarantee they maintain a zero-drip operation.

Fully automated Filling Machines

These are used for large-scale operations and in corporations with high production desires. automated filling machines are typically used with variable-speed conveyor systems and for packaging, liquids with all levels of viscousness and people with suspended particles. machine-driven filling machines will fill 5-10ml of a product and generate 6000 bottles/hour. we tend to primarily manufacture this kind of machine.

According to the filling principle, all liquid filling systems fall under either of two categories: volumetrically or liquid-level filling machines.

And so, this can be the choice you have got to create beforehand: volumetrically or Liquid Level? For the overwhelming majority of merchandise, the solution is going to be liquid-level filling since it’s cheaper and quicker than volumetrically filling, and customers of the product won’t feel cheated once the bottles “appear” to be equally crammed.

Liquid Level Filling Machines

Overflow Filling instrumentality

Pressure fillers have a tank on the rear of the machine with a valve to stay the tank full either by a straightforward float valve or by switching a pump on and off. The tank flood feeds a pump that then feeds to a manifold wherever a variety of special overflow filling heads lower down into the bottle because the bottle fills to the highest, and the excess liquid goes back up a second port inside the filling head and overflows back to the tank. At that time the pump switches off and any remaining excess liquid and pressure are eased.

Volumetric Filling Machines

Check Valve Piston Filler

Check valve piston filling machines use a check valve system that opens and closes on the infeed stroke and discharge stroke. an excellent feature of this kind of filling instrumentality is that it will self-prime to draw product directly from a drum or pail so discharge it into your container. Typical accuracy on a piston filler is minus half p.c. but check valve piston fillers do have bound limitations in this will not run viscous products or merchandise with particulates as each can foul the valves.

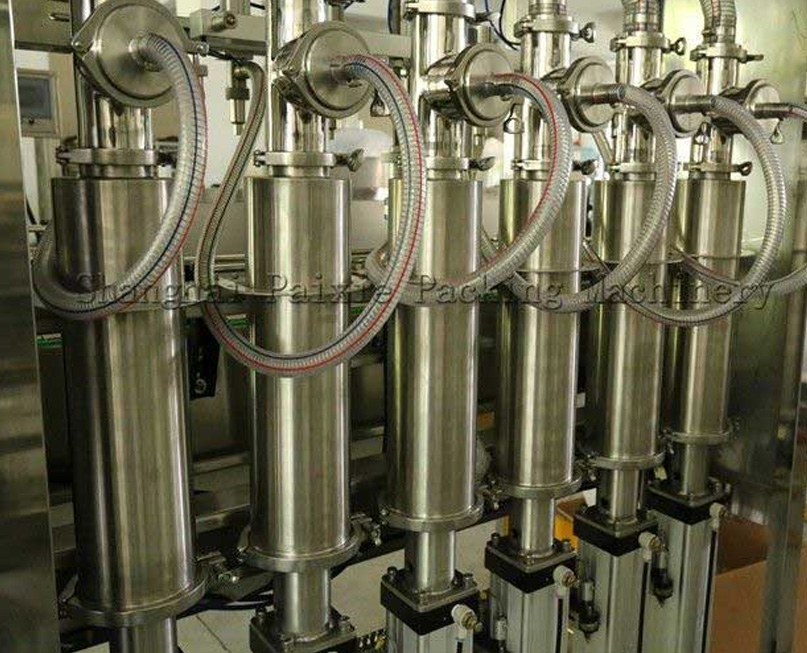

Rotary Valve Piston Filling Machine

Rotary valve piston fillers are distinguished by the rotary valve that encompasses a giant throat gap to permit thick merchandise and merchandise with giant particulates (up to 1/2″ diameter) from the provision hopper to flow through unobstructed. nice as a work surface model or maybe ganged for higher production needs. Fill pastes, paste, gear oil, potato salads, salad dressing, and far a lot of on this kind of piston filler with an accuracy of and or minus half p.c. Fills accurately at a 10 to 1 ratio of the cylinder set.

Pump Filling Machines

Pump fillers are another technique of filling merchandise starting from liquids to thick pastes, even those with solid particulates (although typically abundant and smaller than on a Rotary Valve Piston Filler). obtainable as work surface models through multi-head ganged automatic machines. Another advantage of victimization positive displacement pump filling instrumentality is that the variety of fill volumes is far bigger than on a piston filler, albeit that the fill times increase considerably the larger the fill volume needed.

Peristaltic Pump Filling Machinery

Peristaltic pump filling machines are highly regarded within the pharmaceutical and unsafe chemical industries, as a result, the product doesn’t have any external atmosphere exposure since the hose goes directly from the merchandise provided, through the pump (as opposition into the pump), and to the dispense purpose. once the merchandise run is complete the hose may be disposed of or treated for utilization.

Timed Fill Gravity Systems

Timed flow fillers are another variety of filling instrumentality on the market. this kind of filler works on the principle of a tank mounted higher than filling heads that have magnet valves to open and shut for the flow, or in some cases pinching of the hose to shut. Fill volume is set by timers that open and close the valves or pinch the tubes.

Net weight filling machines – Net Weight filler

Net weight filling machines use a weigh scale platform to observe the burden of the product because it is filling into a bottle or instrumentality. internet weight fillers are similar in temperament for giant instrumentality filling applications. This machine is employed for deliberation and filling 5-30kg liquid. Use physical phenomenon sensing, proximity switch, and different sensing components, so that it may be machine-driven production. victimization of the submersible filling, filling valve diameter, quick feeding, valve mouth intrinsic plug, and no drip leak. will do bottle filling, no bottle not filling. Stable operation, safe and healthful.

WEIGHT-BASED TECHNOLOGY

Automatic weigh metric oil filling machine, fully automatic vegetable oil filling line., cottonseed oil filling machine., automatic tin filling machine. and edible oil tin filling machine, Weight Base 15 Kg Oil Tin Filling Machine, Weight Metric Oil Tin Filling Machine, Jerry Can Filling Machine, Edible Oil Packing Machine, Gulab Sunflower Oil Tin Packaging Machine, Weight Metric Oil Filling Machine designed and manufactured in our production plant. We offer two different filling technologies such as volumetric fillers and weight fillers, in-line or rotary type, presenting different benefits, such as high filling accuracy and quick product changeover.

Weight technology specifically engineered for the Food and Beverage industry.

Weight filler machine with load cell technology, specifically designed for formulated products like sauces, mayonnaise, ketchup for glass, PET, HDPE bottle, Container. Jar and Jerry can, Tin.

- High filling accuracy, fundamental to avoid product waste.

- Non-drip nozzles

- Quick product and container change-over

- Product tank and sliding tracks designed to avoid oil stagnation

- Integrated product change-over devices

Servo-Driven Pump Fillers:

With the value of servo drive controls returning means down over the last ten years a lot of and a lot of uses for filling have gotten play. Gear pump fillers are one variety of applications that have become highly regarded, though you want to take care that the pumps are healthful if you are doing foods, cosmetics, or prescribed drugs. The advantage of the gear pump is that you just will fill nearly any size product while not want for modification elements (although this still has limitations).

Pressure Fillers:

Pressure-filling machines have their tanks below the lowest of the bottle. once filling plastic bottles the pump should be turned off (always for positive displacement pumps) before removing the filling tubes to permit the bottles to come to traditional size (they swell below pressure) and drain off excess liquid. the massive advantage of pressure fillers is that bottles fill a lot quickly therefore fewer heads (and space) are needed, and better viscousness merchandise may be crammed.

Counter Pressure Fillers:

These are liquid-filling machines distinctive to the effervescent liquid business which has brewage, soda, and any sparkling liquid or wine. The heads for this kind of filling encompass three parts: Vent, CO2 pressurizer, and fill tube. the pinnacle seals and therefore the Vent and CO2 pressure valves are opened. The air within the bottle is forced out of the bottle and is replaced with heavier CO2.