Servo Liquid Filling Machine is designed to fill liquid syrups in spherical or flat bottles in intermittent linear motion. It uses Servo Driven Drip Proof NRV syringes for filling operation for that reason giving the privilege to set fill extent from PLC.

This gadget has been Provisioned for Dive-in nozzles as a way to fill foam-primarily based liquid. The layout of the machine is so bendy that multiple heads will be customized with the customer's requirements and velocity.

This Filling Machine is appropriate for Round or Flatform Bottles or Vials with the most velocity of forty Products in line with the minute.

The output of Bottle Filling Machines relies on the nature of Liquids, Bottle Diameter, Bottle Height, Bottle Neck Size and Fill Volume.

Machine creation in absolutely Stainless-Steel finish inclusive of machine frame shape.

This system works at the precept of metering the waft of the liquid via virtual control.

The liquid to be stuffed flows from the reservoir tank to the field via a Gear pump, managed through PLC.

Machine with Optional Turn Tables at In-feed and Out-feed with character drives to shape the Bottles for smoother operation. All machine elements were crafted from Stainless steel. 316 Materials.

Many agencies use a couple of bottles for a single product. Several companies additionally run a couple of products.

In maximum cases, a single liquid filler may be manufactured to deal with all bottles and products packaged through a company.

Some machines will use easy changes to alternate from one bottle or product to another, even as others would possibly require a touch extra time on changeover wherein bottle sizes or viscosity are different from one to another.

Features

- The storage tank is mechanically managed through the implications of excessive/low-stage sensors.

- The machine is provided with a smooth to easy built-in storage tank.

- Drain tray across the system platform.

- Drip tray below the conveyor.

- very easy to clean the bottom of the machine.

- The gadget is synthetic or advanced following GMP standards.

- The machine layout is made compact & flexible,

- The structure is manufactured from SS 304.

The filling is based on a diving system in which nozzles pass in the bottle and as soon as the bottle is stuffed in line with the preferred extent, it comes out of the bottle.

The system of diving and blocking off the goods is accomplished through a pneumatic (air) operated cylinder.

The Air strain indicator is connected with the machine to signify the fault of a low strain of air supply.

Servo motor primarily based filling pump is beneficial to suck the filling material from storage tank to nozzle. Moreover, this facility is beneficial to the easy filling line as well as the filling pump.

If the filling stage is going down (Low stage) then the machine will mechanically prevent and at the identical time, it's going to deliver the fault sign for the Low stage on the HMI screen.

After the crowning glory of the filling system, if the storage tank is needed to be cleaned, there's no need to eliminate the storage tank.

This cleansing system may be accomplished in no time with the assistance of a drain valve.

Any sort of fault in the course of the operation of the gadget such as the low strain of air, low level of liquid, no product, etc. Can seem at the HMI, which may be without difficulty attended.

Servo-primarily based Ampoule filling machines are specially used withinside the pharmaceutical and chemical industries in Asia, the USA, and Europe.

Europe is taken into consideration to be an exceedingly demanded and world-magnificence marketplace of ampoule filling machines.

All of that merchandise requires superior machines to fabricate and bundle them, for example, tablet filling gadgets, ampoule filling gadgets, and liquid bottle filling machines are a number of the machines that producers use for packaging pharmaceutical merchandise.

Advantages

- Increased Production Capacity

Servo-primarily based ampoule filling machines can produce as much as 2 hundred ampoules/in line with minute. Not only does the device have a high manufacturing capacity, but however it's also quicker and extra efficient. It lets in for a quicker changeover, saving time. - Ensure the first-rate hygiene standards

Since ampoules are glass bottles that save the content material, they stay dust-loose and guarded against different pathogens. Whether the drug is stable or liquid, ampoule filling machines can save the precise quantity of content material that guarantees purity and much less wastage. You may even save the contents for a protracted time. - Comes with a pre-warming system

Now you don't need to worry about ampoule filling gadget being overheated. A pre-warming mattress allows the gadget to mechanically warm the mattress which complements the lifespan of the gadget and makes it extra durable. - Easy maintenance

Servo-primarily based ampoule filling machines are smooth to function and the co-eccentric nozzles permit for a fast and particular filling. Simply load the ampoules and the goods you need to fill and you're accurate to pass.

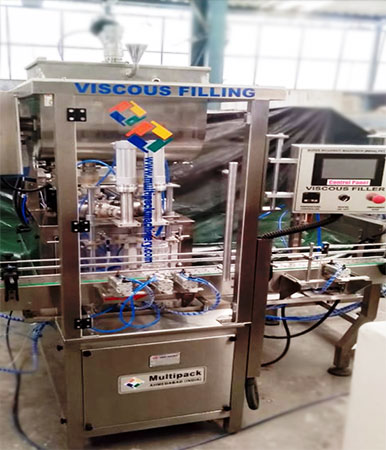

Viscous liquid filling machine and viscous liquid packaging line for semi and solid base products for cream , shampoo, lotion , face wash , hand wash , Hair Products - Dyes, Relaxers, Removal, Hair Smoothing Products That Release Formaldehyde, Solutions , Creams / Emulsions , Lotions , Ointments / Pastes , Suspensions, Gels, Sticks, Aerosols filling line etc for cosmetic industry with different application, technology , speed etc customized designed as per room and container sizes and shape .

Viscous Liquid filling machine used for food industry with different type of product like Sauce , Chutney, ruit juices, including nectars and juices with pulp, Sugar, honey, and syrups, Hot Sauce, Taco Sauce, Soy Sauce ,Tartar Sauce etc...

Our filler machine for Tomato Chutney , Peanut Chutney , Onion Chutney Recipe , Pickle Recipes, Green Chilli Pickle , Garlic, Lamon, Amla, Mango , Green Chilli Pickle , Garlic, Lamon, Amla, Mango filler and Packaging line.

Multipack is leading manufacturing of are one of the famous brands for supplying desi cow ghee packaging line in India. They use airtight packaging for better purity and quality.

Our Ghee filling Machine and Packaging Nutritional Ghee , Pure Ghee, Cow ghee, Desi Ghee ,buffalo ghee , Organic Ghee , Vedic ghee , premium ghee Jar and tin filling , capping , induction , batch Coading and shrink labeling and self adhesive labeling and final packaging to carton boxes.

Please refer our video links for ghee jar filling machine:

Please refer our video links for sauces filling machine:

Please refer our video link for Petroleum jelly filling machine:

Please refer our video links for piston filler machine

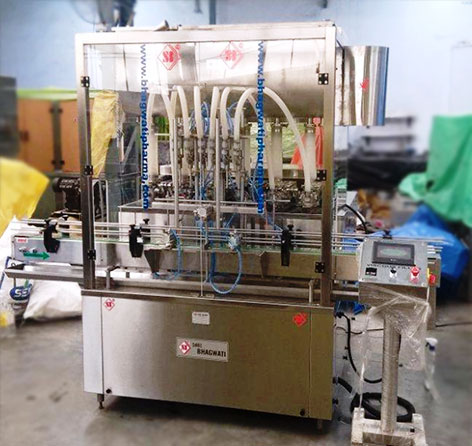

Shree Bhagwati Range Liquid filling line with servo base systems , Auto Servo Liquid bottle Filling Machine consisting of main body structure, products slat transmissions belt systems with adjustable guide for containers and nozzle , products storage tank or mixing tanks, pneumatics bottle stopper systems or star wheel, feed screw depending on bottle shape and speed , LATEST SERVO base Servo Liquid filling pumping unit , Servo Liquid filling nozzle, Machine safety enclosure (OPTIONAL), electricals panel, motors, PLC & HMI, Variable AC drive. HIGH / LOW liquid level sensors in the tank is an added advantage and providing Liquid pump connection systems with Control panel than to fixed by customer transfer pump from storage materials and automatic Liquid leval maintain by machine inside filling machine hopper .

Special for liquid filling line from free flow and thin viscous to high density liquids, such as water type Liquid , edible oil ,lube oil filling , lotion filling , cream filling , Jam filler, sauce filler, honey filler , ketchup filler , olive oil, palm oil, soybean oil, canola oil (rapeseed oil), corn oil, peanut oil , tomato paste, honey, jam, gel, peanut butter, oil, shampoo, lotion, cream, etc and mostly used in the industry of Pharmaceutical , Agro chemical, Bio Pesticide, chemicals, foodstuff and Biodiesel.

The bottle filling systems is drive by servo motors which assuring high accuracy filling. filling volume controlled by the PLC, human interface and User friendly easy operations.

Bottling machinery needs. Different type of filling machine and packaging line used to liquids, pastes, chunky products, powders, granule, tablet, capsules etc….

- Vinegar Filling Machine

- Sunflower Oil Filling Machine

- Paste Filling Machine

- Salad Dressing Filling Machine

- Sauce Filling Machine

- Syrup Filling Machine

- Palm Oil Filling Machine

- Olive Oil Filling Machine

- Mustard Oil Filling Machine

- Mayonnaise Filling Machine

- Ice Cream Filling Machine

- Hummus Filling Machine

- Ghee Filling Machine

- Edible Oil Filling Machine

- Cream Puff Filling Machine

- Cottage Cheese Filling Machine

- Cooking Oil Filling Machine

- Coconut Oil Filling Machine

Food and sauce bottling machinery needs.

- Chocolate Filling Machine

- Butter Filling Machine

- Peanut Butter Filling Machine

- Maple Syrup Filling Machine

- Ketchup Filling Machine

- Jam Filling Machine

- Honey Filling Machine

- Fruit Jam Filing Machine

- Chocolate Jam Filling Machine

- Chili Sauce Filling Machine

- Apple Jam Filling Machine

Chemical filling Machine and Packaging line-system, along with a complete liquid packaging line.

- Ointment Filling Machine

- Paint Filling Machine

- Resin Filling Machine

- Pesticide Filling Machine

- Grease Filling Machine

- Ink-Filling-Machine

- Cleaners and Degreasers Filling Machine

- Vaseline Filling Machine

- Solvent Filling Machine

- Lubricant Filling Machine

- Liquid Soap Filling Machine

- Laundry Detergent Filling Machine

- Glue Filling Machine

- Engine Oil Filling Machine

- Coolant Filling Machine

- Brake Oil Filling Machine

- Brake Fluid Filling Machine

- Bleach Filling Machine

Technical Parameter

Manufacturer of servo base liquid filling machine, servo liquid filling machine, shampoo filling machine and servo driven liquid filling machine , Filling Line Machines Included

- Pharmaceutical And Biomedical Filling Line

- Automatic Chemical Filling Line

- Automatic Lubricating Oil Filling Line

- Personal Care Product Filling Line

- Household Product Filling Line

Gel Filling machine

Gel filling machine different type gel textures like shampoos, creams, aerosols etc. This filling line equipment is also best suitable for filler gel like product to containers and tube. We manufacturing gel manufacturing plant , mixer and filling line equipment’s with Capping / sealing / labeling accessories to make gel packaging best fast Clean pack and cost effective.

Gel Filling machine

Liquid and packaging solutions that we have for your household product applications.

Detergent Filling Line

- Bottle Feeding Turntable

- Automatic Piston Liquid Filling Machine

- Automatic Rotary Capping Machine

- Bottle Working Table Rolling Type

Glass Cleaner Filling Line

- Bottle Feeding Turntable

- Automatic Gravity Filling Machine

- Automatic Capping Machine

- Automatic Double Sides Self-adhesive Labeling Machine

- Bottle Working Table Rolling Type

Detergent Filling Solution

- Bottle Feeding Turntable

- Automatic Anti-corrosive Gravity Filling Machine

- Automatic Capping Machine

- Automatic Double Sides Self-adhesive Labeling Machine

- Bottle Working Table Rolling Type

Peanut Butter Filling Line

bottling peanut butter filling line with several types of filling technologies machines ..

Our peanut butter complete line of packaging equipment including peanut butter filling machines for a wide range of viscous substances, Screw capping machines, induction sealing machine, Checkweigher machine conveyors, labeling machines.

Filling line 2 nozzle to 16 nozzle filling line available depending of requirement