Piston Filling Machine

The filler is an essential equipment for the manufacturing industry for promoting quality and efficiency of the products during the manufacturing process. They are usually employed for packaging food or beverage, but their use extends to the packaging of many other products as well. However, different fillers are required for various products. And these products are packaged in a specified amount in a carton, a plastic bag or a bottle.

Based on their degree of automation and the materials used, these fillers are classified differently. They could be categorized as automatic, semi-automatic and fully automatic machines. And they could also be liquid fillers, gas fillers, paste fillers and powder fillers.

It is important to note that there are various types of fillers in the market when we talk about the working principles. Therefore we will only look at the working principles behind the filling of liquids, gases, and adhesives.

This unifiller piston filling machine is specially made for viscous liquid such as concentrated juice, honey, butter, and cream, applied to bottle of all sizes. It is widely used in industries such as food, beverage, All-Fill Viscous Liquid Filling Machine best suitable and many machines installed For Filling Jams, Sauces, Squashes, Food pastes, Chutneys, Ghee, Pharmacy Suspensions, Adhesives, Cosmetic Creams & Lotions, super pack Lubricants, Oils, Juices, Health drinks, Ayurveda Preparations, Pharmacy Formulations, Syrups, Pesticides, Bio-Chemicals ,Fertilisers & Pesticides Filling Machine, Liquid Disinfectants Filling Machine, Liquid Food Colours Filling Machine, Liquid Chemicals Filling Machine, Liquid Detergent Filling Machine, Liquid Soap Filling Machine, Aloe Vera Juice Filling Machine unifiller, a pack Inks Filling Machine etc. Installed machines to Canada, USA, UK, Indonesia, Thailand etc. many more Liqpack, liquid pack filling range machine technologies from German, UAS, and Italy with collarbrataiton base. Cosmetics etc.

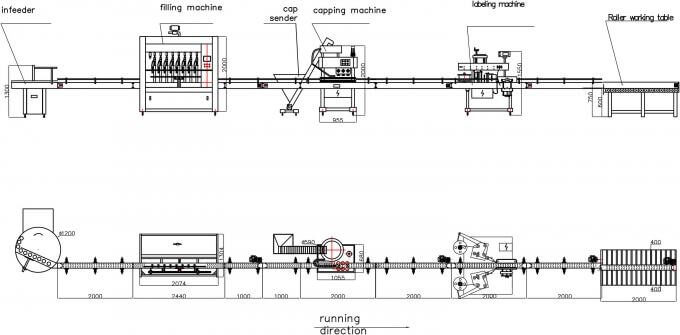

This liquid piston filling machine is full automatically, it is suitable for all kinds of bottles, and no matter plastic or glass both round and square are OK. Connecting with capping and labeling machine can form a whole production line.

The liquid filling machine is reasonable in design, simple and beautiful in appearance, and easy in filling volume adjustment. Adopting bottle positioning system and liquid level control system, adopting German FESTO, Taiwan AirTac pneumatic components and Taiwan’s electrical control parts, the performance is stable.

We use the best components, CE standard, all metal parts are made of stainless steel, which makes machine stable and durable, meet the standard of GMP. We have exported many machines to many countries abroad, customers response are good. Finished machine are packaged in strong seaworthy wooden cases.

Machine can be customized according to customer’s request. We produce machine according to the bottle sample so that finished machine can be perfectly suitable for your products. We take working video with your samples for you to check after machine finished.

Main Features of Piston Filling Machine:-

- The automatic Honey / Beverage and Cosmetic Filling machine is designed by our company in the reference overseas similar product, and adds some additional function, which makes the product more simple and convenient in operation, adjustment, cleaning and maintenance.

- The Honey / Beverage and Cosmetic filler is reasonable in design, simple and beautiful in appearance, and easy in filling volume adjustment.

- The parts contacted with material are made of 304L or 316L stainless steel.

- No bottle no filling. Equipped with count function. Bottle positioning system and liquid level control system.

- Adopting German FESTO, Taiwan AirTac pneumatic components and Taiwan’s electrical control parts, the performance is stable.

In paste fillers, a volumetric method is used for measuring and controlling the filling quantity of the pastes. This method is considered very efficient and easy to maintain. It is particularly handy for highly viscous products.

This machine is based on a self-priming cylinder in which a piston can move. The piston diameter along with the stroke length decides the filling volume. The volumetric fill of this liquid filler is considered highly accurate because of the constant volume of the cylinder on the piston.

This machine is with a hopper on the top, especially suitable for filling viscous liquid such as tomato paste, peanut butter etc. The hopper is to store the liquid, made of SS304 (SS316 is optional), double jacket, has function of heating and keeping warm. This guarantee the fluidity of liquid. Equipped with piston pumps, especially suitable for viscous liquid.

This Piston filler is an extremely flexible filler capable of filling accurately and rapidly any viscous liquids. Product delivery from your bulk tank to the pistons can be configured with a buffer tank utilizing a level-sensing float, a manifold with direct draw, or re-circulation methods.

The Piston Filler is manufactured with a 304 stainless steel frame and is capable of supporting 1 to 12 fill heads. PLC controls, touch screen HMI, food grade contact parts, stainless steel and anodized aluminum construction and many more features come standard. Piston Fillers are designed to add efficiency to any production line used in the cosmetic, food service, specialty chemical, pharmaceutical, and personal care industries. Additional options are available for sanitary, hazardous, flammable and corrosive environments.

Bottle Foil sealing machine suitable Bottle and Jar , Roll foam foil coming and cut from die and fixed with Jar neck with hot sealing , before capping machine foil sealing application to avoid manual operation .

Three Head Label applicator with Conveyor for high speed filling line …. One label applicator is apply label and roll is over than second label applicator is starting automatic apply label to Jar, bottle or any kind of surface and applications.

Inline capper with cap feeding automatic systems for large size jar / Jerry can , bottle etc fixed with automatic filling line , we deigned capper as per Container and caps samples

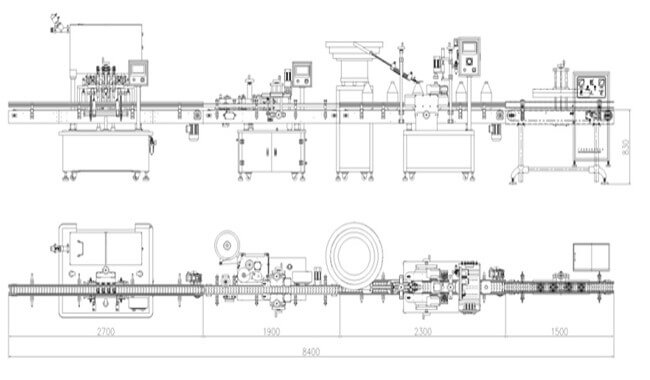

Piston Viscous Filling Machine Layout

Piston Filling Machine Specification:-

| Filling material | Tomato paste, peanut butter ,petroleum jelly, Soda / Juice etc. |

| Filling nozzles | 2/4/6/8 nozzles(can be customized by customers) |

| Filling Volume | 30-2000ml( can be customized by customers) |

| Polyester Bottle Standard | bottle diameterΦ50-Φ500; height 50-500 |

| Filling speed | 1000-3000bottles/hour |

| Filling precision | ±1%(Liquid level) |

| Gas Source Pressure | 2~3MPa |

| Power | 220/380v 50/60Hz |

| Total power | 1Kw |

| Single machine noise | ≤50dB |

| Weight | 600 KG |

| Machine size | L2500*W1000*H2000mm |

PRODUCT APPLICATION

Honey -: honey filling, vinegar filling, fruit syrup filling

Food Pastes -: Ginger paste filling, garlic paste filling, food paste filling, vinegar filling, juice filling, pulp filling, ghee filling, curd filling, dahi filling, ice-cream filling, butter filling, cake paste filling, mayonnaise filling, yeast filling

Ointment -: ointment filling, gum filling, syrup filling

Adhesives -: paint filling, adhesive filling, fevicol filling, paste solution filling, rubber adhesive filling, resin filling, hardener filling, silicon sealant filling

Creams -: cosmetic cream filling, shampoo filling hair lotion filling, shaving cream filling, mouth freshener filling, hand wash filling, face wash filling, tooth paste filling

Balms -: lotion filling, balm filling

Global Demand of Piston Filling Machine:-

This Piston Fillers market study offers a comprehensive analysis of the business models, key strategies, and respective market shares of some of the most prominent players in this landscape. Along with an in-depth commentary on the key influencing factors, market statistics in terms of revenues, segment-wise data, region-wise data, and country-wise data are offered in the full study. This study is one of the most comprehensive documentation that captures all the facets of the evolving Piston Fillers market.

Filling has become an integral part of the packaging industry in recent years, and thus the growing packaging industry is fuelling growth in the filling equipment industry. Additionally, the rapidly advancing technology in tandem with the growing focus on process automation has changed the way filling equipment sector works. Consequently, manufacturers are increasingly developing novel filling equipment to meet the evolving consumer preferences and needs, which has further driven the applications for such equipment.

Piston filler is a widely used conventional filler with wide applications in the proliferating packaging industry. They are widely adopted for filling highly viscous and thick products, such as paste, semi paste, and chunky or for viscous chemical preparations, including epoxy’s, lubricant oil, waxes, grease, adhesives etc. Companies are increasingly leveraging piston fillers to comply with the stringent food grade standards, as this equipment measures a product using a reciprocating piston of a present volume.

Piston fillers are based on a low cost, conventional technology, which is very easy to understand for most users. As this filling equipment provide fast filling rates with fairly thick products, they have been used widely in the recent years. However, the advent of servo positive displacement fillers has hit the growth in piston fillers market.

Here you can explore the process of the piton filler process